Client: Progress Holding AG

Sector: Leader supplier in the industrial pre-fabricated concrete sector

Type of intervention: Implementation of a new factory in Bressanone (BZ)

Issue:

The expansion of the Progress group in the industrial area of Bressanone is achieved through the construction of a new hangar for production purposes and offices for management. The working team involved in the project design addressed many challenges, both technical and logistical.

The expansion of the Progress group in the industrial area of Bressanone is achieved through the construction of a new hangar for production purposes and offices for management. The working team involved in the project design addressed many challenges, both technical and logistical.

Indeed, with respect to the hydrogeological aspect, the presence of groundwater, above the level of the building foundations, requires planning a dewatering system that would allow to briefly lower the water level. The use of deep foundations (columns and jet grouting), as well as a restricted timing and the complex logistic related to a yard of this size made this project even more challenging.

What we proposed:

The intervention proposal elaborated by the Geoengineering group was developed with two main goals: first, to design an efficient technical solution, consistent with the worksite logistic and, secondly, to elaborate a solution that would reduce the costs of intervention. To achieve this, an in-depth geotechnical survey was conducted, in order to elaborate an accurate hydrogeological model. Two major criteria were studied during this survey:

The intervention proposal elaborated by the Geoengineering group was developed with two main goals: first, to design an efficient technical solution, consistent with the worksite logistic and, secondly, to elaborate a solution that would reduce the costs of intervention. To achieve this, an in-depth geotechnical survey was conducted, in order to elaborate an accurate hydrogeological model. Two major criteria were studied during this survey:

- The local lithostratigraphy, through the G.R.M method (seismic refraction)

- The characteristics of the superficial aquifer, testing the extraction of the groundwater, in order to predict its long duration behaviour and to put in place a punctual dewatering system

How we act:

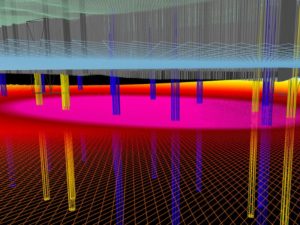

The previous data, obtained through the geotechnical surveys, were integrated into GIS/MODFLOW software, allowing the reconstruction of the local lithostratigraphy and the groundwater flow. Based on this last model, a pumping system was designed, allowing us to predict the combined effect of multiple wells system. During the planning phase we also managed the relationship with dewatering system suppliers, helping our client carry out all the technical issues and coordinating every stakeholder involved. We were successful in putting in place an efficient dewatering system, tailored to the logistic needs imposed by a challenging working schedule during the construction.

The previous data, obtained through the geotechnical surveys, were integrated into GIS/MODFLOW software, allowing the reconstruction of the local lithostratigraphy and the groundwater flow. Based on this last model, a pumping system was designed, allowing us to predict the combined effect of multiple wells system. During the planning phase we also managed the relationship with dewatering system suppliers, helping our client carry out all the technical issues and coordinating every stakeholder involved. We were successful in putting in place an efficient dewatering system, tailored to the logistic needs imposed by a challenging working schedule during the construction.

Share this Post